Our products do not require any certification from the AGA, CSA or UL as it is considered a stand-alone product. We are told that we need certification if sand and or lava rock would need certification. The agencies are franchise operations and they are privately owned and they are not a government agency.

These agencies are hired for mass production testing and AGA, CSA and or UL do not certify custom one of a kind projects. Custom burners need no certification as this only applies to production equipment. Just so you can understand that a certification costs about $15,000.00 and certification was developed for production/ mass production to assure quality.

Any parts that would normally need AGA or UL do in fact have these approvals. Parts with function need and should have some sort of approval. The pan burners we sell that do have UL, CSA and or any other listings are produced by other companies.

The custom pan burners that we produce are just that, custom. Therefore do not require UL, CSA and or any other agency listings as these are custom. The parts that we use to build these pans are UL, CSA listed as they should be. We would never use any “Third World Country” or any unlisted, untested parts to build any products and or parts to endanger any product performance what so ever.

We use 25,000 btu's per linear foot when calculate customs for 10~12" flame. For standard burners we actually hook to meter and measure at 800' elevation.

Currently under-development, our latest product "tubED" is

a fire feature that uses sound waves to electronically excite

gas molecules. Check out the Video Here.

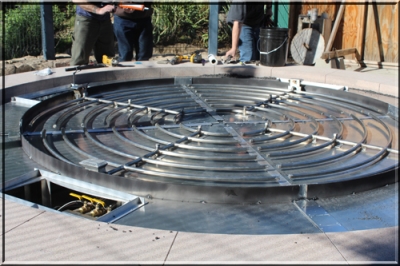

This large fire fit required a 4 in 1 manifold, four 304 grade stainless steel quad rings along with a LP/propane HWI 2 pound system with 60" lead. We can't wait to get the final pictures with the media installed.

Click on the video below. You can watch full screen if you click the button with the 4 arrows pointing outwardly in the bottom right corner.

__________________________________________________________________________

CLICK HERE or on the pictures below to see how Knott's Berry Farm fire pit finished!

__________________________________________________________________________

A real one-of-a-kind pan, our client had his custom pan Copper cladded. Turned out great with a nice contrasting Azurlite Base Glass FireGlass for filler. You'll also notice the amount of reflection coming from the back, that's because the back of the pan had a chrome finish which casted a back-lit effect.

What's so nice about Copper metal, is that it rust so nicely, very classy!

This custom pan was specifically designed to be placed in a rectangular housing structure.

Ty Havas didn't want an ordinary Propane pan for his fireplace. He wanted a pan that would be more than functional. So after some sketches and discussions we began making a cardboard mock up.

He would ultimately receive a Stainless Steel pan with angled legs and a 2 inch depth. Here the cardboard mock-up along with his fireplace measurements (which you can see denoted on the cardboard piece below the mock-up) assure that we attain the correct size and appropriate design.

The fireplace is emptied out and it becomes apparent that its in dire need of a

fresh coat of paint. And since the custom pan was built with legs, the fireplace floor will be left visible and as a result fresh tile will be added to the hearth.

The fireplace re-design is complete with two custom reflective

sterling silver panels on either side of the pan to give the illusion of the fireplace being larger.

The stainless steel pan is filled

1/4" Bronze Base Glass,

1/4" Bronze Reflective Base Glass,

Copper Ruby Red Topper,

Yellowish Opal Orange Topper, and

Red Brown Topper.

A wonderful transformation.

Here's a particularly beautiful mess from our

How Not Do To It page. This propane fireplace comes to us from Seattle Washington.

Not exactly sure whats surrounding the propane pan, but what is clear is though, is that the flame output is pathetic! And that the glass has been destroyed.

Here the old pan is removed and the fireplace is prepared for the new pan by creating a cardboard mock up.

The new pan we built is then installed.

And the

Platinum Base Glass FireGlass is added.

Ignite and enjoy a clean burning propane fireplace.

The stainless steel pan burner below has a 24" stainless steel star burner installed and it is connected to our 110 volt

electronic ignition. This is a

propane burner.

We then covered it with our

Starfire Base Glass to test for soot and as you can see, a clean burn.

The pan below is a stainless steel pan with a 415,000 btu

electronic ignition installed under the pan. It's what the customer wanted. It's like hooking your car up the the shuttle for more power. This pan was installed in Nipomo/ Pismo Beach California, Shea Homes and we get up there we will take finished pictures as we installed 6 other fireplace which we will take pictures of as well. The front stainless skirt hide the control box which is 4" tall.

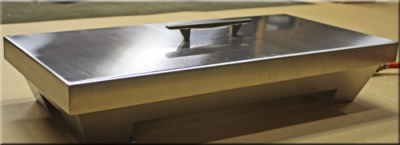

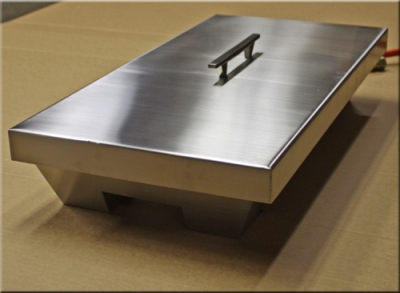

The stainless steel pan below has a 3/4" lip on top and it sits on 4" round brushed front legs.

The fireplace below is the fireplace of "Bill" and he wasn't sure where the burners went. So he put them on top and as you can see he should of put them under the glass. Bill ordered a rectangular pan and it would of looked better if we would of built a trapezoid shape pan to contour the fireplace. Bill did drop his burners under the glass. This was a propane

ventless conversion. Looks much better than those log thingies! Hopefully Bill will send us pictures of it finished and burning, maybe. We used

Starfire Base Glass in the pan.

The fire pit below was build by Mike Phillips ( a customer). First he ran a propane line to the fire pit area and then blocked his fire pit into shape. We use a FPPK (fire pit propane kit) in an aluminum pan 24" x 24" with a double 18" double stainless steel ring.The glass that was used was Gray Base Glass with a Gray Reflective Base Glass on top to add sparkle. Below you can see the placement of the thermocouple and safety pilot light used for propane. Below on the right side the controls were installed in the bricks.

The pan below is a stainless steel pan made to the same size as the fireplace. We installed a front curtain to hide the controls. This is a

propane ventless burner pan. We will post pictures when the customer sends them to us after the installation. We installed a 30" double burner in the middle. The maximum btu's on a

ventless is 38,000 and any larger burner will make the flames much smaller. Below the customer wanted sculpted front legs.

Below you see the front curtain in stainless steel.

And here you have it burning with the glass.

And the rest of the colors for one nice design from George!

You can see the front plate that was painted to match which is removable if and when necessary to change the batteries. The legs were 4 1/2" and the pan was 2" tall. The removable front metal curtain was 6 1/2" tall.

The pan below was created by John Webber of San Diego. He made a cardboard mock up of what he wanted in his fireplace and we duplicated it in stainless steel. Here is John's fireplace now, our pan and we will posts pictures of the finished fireplace with our pan when John sends them to us. The glass that was installed in this pictures of the pan is Pink Rosa Base Glass.

John ultimately decided on Starfire Base Glass FireGlass.

Here is the custom burner pan installed.

The propane pan below has a brushed finish on the front metal shield. This is a two part shield, one to retain the fireplace glass and second to conceal the controls. This is part of the fireplace design that was asked for. The first pictures shows the front completely up.

The picture below shows the complete front dropped down to access the controls.

The burner below is a propane ribbon burner with all stainless steel construction.

The pan and all around was filled with glass hiding/ concealing all of the workings. A ribbon burner will mold all of the flames together making it look like a ribbon of fire.

Below you will see how simple it is to convert/ install a propane into your table: This is our FPPK box with controls and air mixer calibrated to the burner we are using.

The burner on the top side with the thermocouple, pilot light and battery operated ignitor exposed. Pour the filler lava / FireGlass? and drink beer! Put a fork in it, You're done!

The next few pictures are from New York by Jai Crandall for Tom Morgan. We can help transform an eye soar to a place of enjoyment. Just watch!

November 10, 2009

Hello Ed, my name is Jai Crandall and I live in central NY. I have a good friend (Tom Morgan) that has a patio that he generally uses wood to throw some heat for his quests when he entertains. Unfortunately, as I'm sure you know, the smoke can really get to you after a while. This is a very high end home and he entertains for some very important people. He would like to eliminate the wood a replace them with some propane inserts. It doesn't have to look like a fireplace, but most importantly, it needs to throw some intense heat.

Pictures 1,2 and 3 are the front views of the fire pits and as you will notice they are not square ( each picture is labeled with the dimensions), they don't need to stay like they are, so if you want to make them square you can. Just go by the front measurement. Hopefully you can design something that will fit there needs.

I am sure that they are going to want electric ignition, and you can try to place the control valves in the front. Also, with the good New York weather, you want want to have covers for each unit.

Thank You so much for your time and I look forward to working with you to complete this project.

Jai Crandall

July 3, 2010

Now here are the finished pictures on the property. Very nice!

Hey Ed, Here are some pictures of the burners that I installed. They look great and they are very happy with their performance. Also, I believe that I may have a few more people interested in something similar to what I did for Tom Morgan. Have a great forth weekend and I will talk to you soon.

Jai

Here is what was fabricated to replace those old ugly grills.

Jai came up with the Stainless Steel hollow base design and we went to work. This is a happy ending! Our propane burners were set to 100,000 BTU's each for maximum heat. The glass that we used was Bronze Rust Copper Base Glass.

The next pan (pans burners and baskets) is a ventless conversion. We cut the pan with a 1/2" front and a 2" back. We bent the front to be removable but also hide the controls. We Build to your needs and imagination! Be sure to see our Metal Page!

______________________________________________________________________

Click HERE or on the picture to see how it was transformed to this!

From THIS! (BELOW) again YUK!

_____________________________________________________________________

"CLICK HERE" to see how it was made or "CLICK on the PICTURE" below

_____________________________________________________________________

_______________________________________________________________________________

Click HERE to see how it was made, allong with Videos or on the pictures below:

_____________________________________________________________________________

______________________________________________________________________

Page 2 of Firpelace Pans, Burners and Baskets

Page 3 of Fireplace Pans, Burners and Baskets