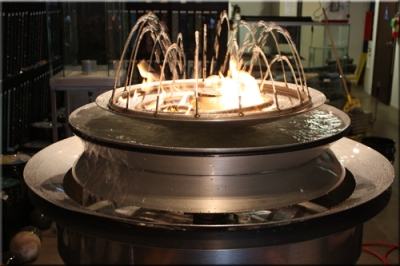

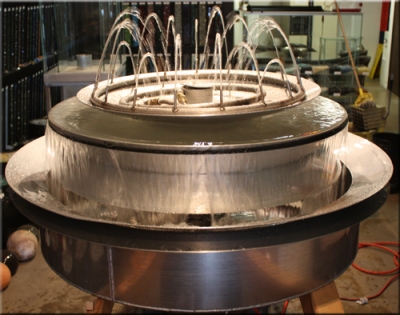

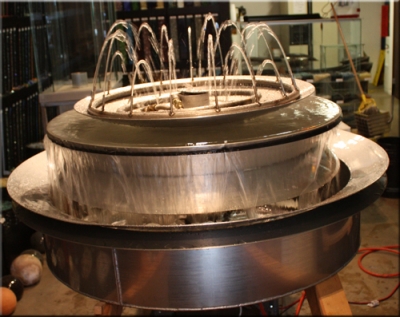

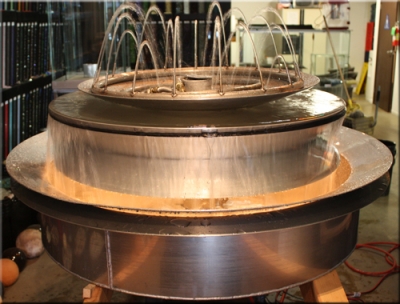

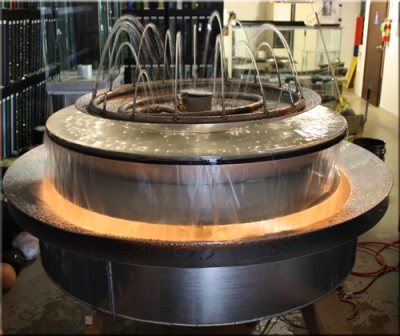

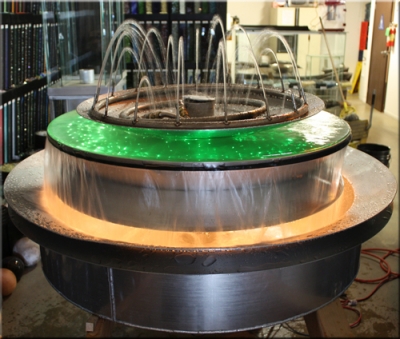

The next fire and water feature is one of our newer designs. The base bowl is a 24" spun aluminum bowl and the fire bowl is a 16" spun aluminum bowl. We will show you how it is made and tested.

The

next few pictures are of a simple water fire bubbler. These can be built for propane or natural gas.

You can add as many features as you like or want...

Metal Logos! We can create any logo in any size or design! Place your colors in our awesome frames and you are set! You can use any of our Toppings to accent the interior or exterior of your Logo or Name! Put this in your fireplace or fire pit with FireGlass in any color!

The first one of many we have created we will soon enough have pictures following with it installed burning.

Here is the first one:

The customer chose one of our Lipstick Reds for a center accent.

The overall size of this "KU" was 6" wide x 9" tall.

Below we used a Cobalt Blue Topping with a Starfire Base Glass all around.

This next fireplace was installed in Mexico by Roy Quick. It turned out amazing. The base glass that was used is:

1/4" Clear White Base Glass

and Scarlett Toppers

accented with Gold Base Glass on top of it all.

The propane pan has a removable front skirt/ cover to conceal the controls.

The next propane fire table was built by Rick Kasner in Arizona, great job! We inspired and supported Rick through out the complete project on "How To Do It Yourself"! DIY!!!

The glass that was installed is:

1/2" Frosted Base Glass

3/8" Gray Base Glass

Gray Topper

Irridizing Amber Brown Topper

We will explain as we move forward.

Base steel stud frame

Propane valve installed

Back side of valving and air mixer.

Durock is now applied.

Durock is finished

Table top is installed

Colors installed in propane pan burner

Drink beer, you are done!

The next Fire and Water is installed in Cafe Vino in Fort Collins Colorado:

http://yannr.com/the-aperitivo-crew-cafe-vino-fort-collins-fb

or click "HERE"

or even

www.CafeVino.com

They built the table and we provided the feature.

Cafe Vino 1200 South College Ave Fort Collins CO 80524

The next fireplace was a self installation by Chris in Palm Springs California. He used about 3" of a sand base under the Starfire Base Glass. Then he added:

Here we go:

The next table was built for a customer in La Jolla California. The table was 30" x 60" with a 24" x 54" fire pit area. They are going to make their own granite top to overlay.

All metal construction and their granite cut and installed.

The next fireplace installation was by Vito

Sanfilippo. He installed a

propane pan and topped it with:

and added

Here we go:

YUK, no paint...

Paint makes a world of difference.

Pan and glass installed

Small fire

and if Vito wants a big fire, Vito gets a big fire!

and his wife said, no I want a small fire, guess who won?

The next Water Over Fire Feature can be made in any configuration, size or shape. We can install it in a table or leave it as a stand alone feature. What ever you like. This particular bowl is a spun aluminum 30" bowl with a 26" water ring and about 100 lbs of Multi Mix Base Glass. We added a few of our Terra Cotta Fire Balls in the center.

The next 27 pictures are of the Dominic Fire Water Feature finished and ready for crating/ shipping.

Here we go: The pictures explain themselves.

This next Vortex project belongs to Alfie Petit in Palm Springs, California.

Alfie designed and had the seating area built to accommodate the Vortex. Then we installed a 42" centerless stainless steel ring which made a fire pit all around the Vortex. Those pictures will be posted as soon as Alfie sends them!!!!!

We will explain as we move forward

Now we wait for Alfie to send evening pictures with the outer ring burning around the Vortex!!!

The next fireplace is a self installation by Harminder in West Covina, Californa. He installed Starfire Base Glass after he installed the 3 Sterling Silver back panels.

The only mistake that was made is that the glass should of been higher to cover the gas line coming in on the right side. He should of added more of a sand base, brought the sand and glass out of the fireplace for a more refined look. That is unless you like pipes!

This next fireplace was installed by

Sueun. She installed the

Sterling Silver back panels and then placed a layer of

sand. Then she installed

Starfire Base Glass over the sand.

Sueun could not decide on which color, she she added almost all!!!!! She added;

Toppers, If she wanted color, then she got it. I think it turned out very colorful.

The next two fireplaces were installed by Joe Socco in Las Vegas, J S Interiors Gouup.

It was featured at The Jenson Group Realty online article. The two fireplaces both had Starfire Base Glass installed.

Here is the home and fireplaces:

http://thejensongroup.com/news/how-to-choose-your-perfect-home-2/

Joseph Sacco

P: 312-404-4665

ASID, NCIDQ #023899

www.jsinteriorsgroup.com

Jim Cogan Created this next fireplace using a Bronze Rust Copper Base Glass. He installed a Ribbon Burner opposed to a regular double burner. He had us make a 1/2" piece of Starfire as a front shield to contain the glass and it served as a "draft offset" to keep the Ribbon Burner traveling straight up. Here are the before and after pictures:

The next pan burner is a propane pan burner with Skytech Controls. This unit has a standing pilot light with a remote control. Th conceal the controls we manufactured a removable lift off front plate.

The next pan was built to the customers specs (round with 3" lip) and wrinkle finish powder coated.

Propane as well.

Note the thermo couple, pilot light and Copreci valve. We calibrate every burner to burn clean.

The next pan was built to the customers specs (round with 3" lip) and wrinkle finish powder coated.

Propane as well.

Note the thermo couple, pilot light and Copreci valve. We calibrate every burner to burn clean.

The next fire table was built by Brian Johnson of Omaha Nebraska, very nice! We supplied the components and Brian did the hard part, the table.

We don't have the construction pictures but we do have the table finished. Add

Bronze Base Glass and to pit with 1 lb of Ice Ice Ice Topper, you are done.

The blue is actually food coloring.

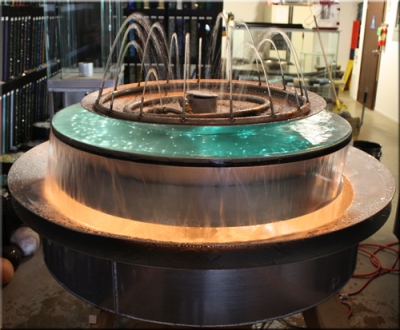

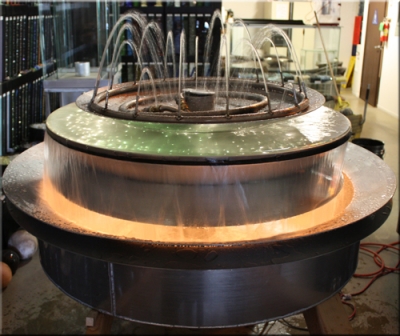

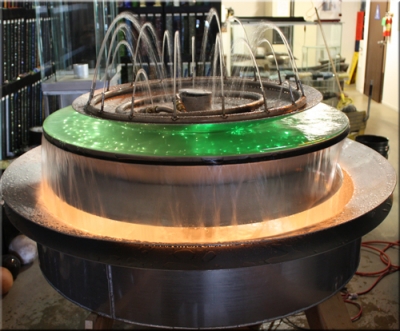

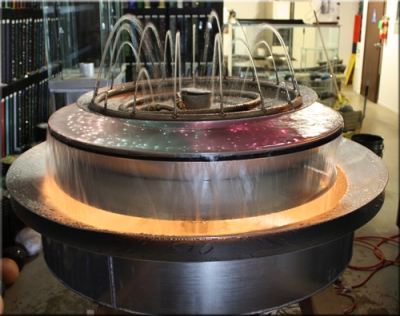

The next Fire and Water features were built for Cafe Vino in Denver Colorado.

The water in the holding tank spins and gets pumped up to the inside of the fire bowl which drips it out back into the water tank.

The water tank has lighting installed in the upper edge. There are many different types of lighting which can be installed.

These only require a 16" hole for the upper bowl to come up and through. The tank is mounted from the bottom.

The fire bowl raises and lowers to increase or decrease the water/ white noise created.

The next picture is of a Black Base Glass, Ice Ice Ice topper and red Porcelain coated fire balls (Terra Cotta)

The next fire pits were designed and built for the Marriott (Islandia previously) in Mission Bay California.

We started with several cardboard mock up tables for the hotel to approve.

We will explain as we move forward.

The hotel decided on the granite and we cut the granite with water jet and polished the edges.

These were installed on the private patios of the hotel suites.

Valves and location are important as well.

They ended up using a thermo couple and pilot light system with a battery operated igniter.

The next pan is a stainless steel pan we manufactures for our customer in Hawaii. The system that was install was a

ventless burner to burn

propane with our glass. We will explain as we go forward.

On the front of the pan we we bend an open back hemmed stainless steel curtain to conceal the controls but it is still easy access.

This is the ODS (Oxygen Depletion Sensor) it speaks for its self.

Here we are burning propane with a

Starfire Base Glass, please note what a clean burn! We do it right.

All of our pans are built for each application and fireplace.

The next fire pit was built for Chuck Krallman in the Bahamas. The challenge was 15 knots per hour trade winds and propane. Not a problem. We mock up all of our projects to insure that they work properly. I will explain as we move on.

We first start testing the venting and use cardboard or plywood only later to be replaces with 1/2" glass panels.

Proper venting and maintaining an upward draft is very important.

Hopefully Chuck will send us the finished and installed pictures of the feature installed in his table.

This is our trailer as of August 2011

We keep modifying and adding to the display.

Our latest addition is the Fogger System by www.Fogco.com.

We will explain as we move forward:

We are just finishing setting up at Palm Springs.This is our 5th year there! Every Thursday evening.

As the evening approaches the fires get larger and more spectacular.

We carry 150 gallons of water for the Fogco System in the back of the truck.

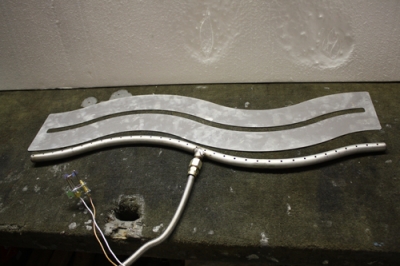

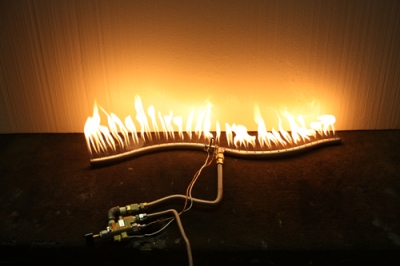

We can build any size, shape or configuration of burner that you may want. The next "S" burner was made to a template from #304 stainless steel pipe. This particular burner was made for a propane fire pit. But it also can be used for natural gas as well.

The next fireplace is in Tennessee and was installed by Rocky. Interesting fact, his house sits on the state line. When you go out of the back door you are in Mississippi!. We built a control / key box (now located in the front of the fireplace) to turn his fireplace on which he never had. Rocky installed a Starfire Base Glass and topped it with 2 lbs of Mixed Toppers.

There is about 4" of sand underneath.

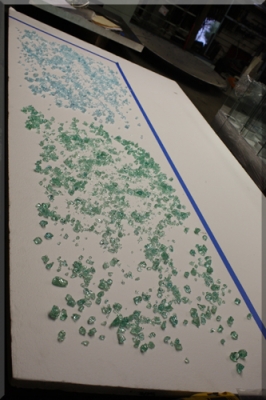

We were providing

Toppers for the Marriott and we were asked to show how much coverage 2 lbs was. So we laid out 30" x 70" area and spread out 2 lbs of each of the colors they wanted to add the top to see if in fact it was enough color.

The next fire pit is from Ivan Grace in New Zealand. We supplied the parts and imagination and he constructed one very nice fire table for his outdoor bar.

We will explain as we move forward.

Above is the wine barrel fire pit with out the granite top.

Below Ivan installed the granite top.

The drink a bit differently in New Zealand than we do here.....

Ivan had a nice top made for his fire pit.

I think Ivan should make a top for his wife next, ya think? But then again it could be catchy here too!!!!

The next fire pit was a customer conversion with our FPPK propane attachments and burner.

What ever project you are converting or working on, we monitor your project all the way through. Provided you send pictures.